Push Button. Paint Building.

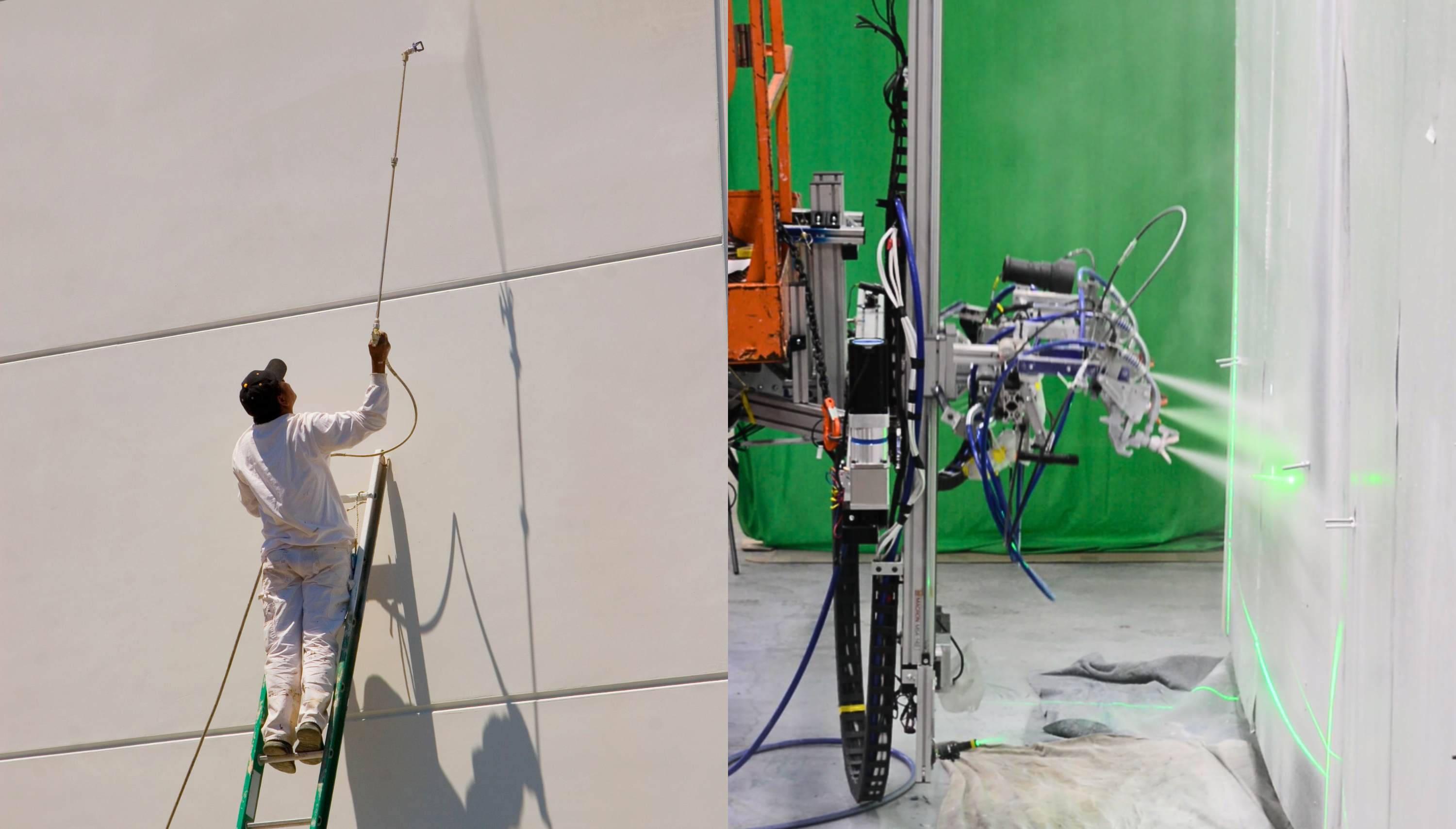

Automation is taking the world by storm, and not just in the industries you would expect. Recently, innovative robotics has produced revolutionary advancement in commercial painting: The ability to prepare and coat any size surface in an even layer of paint without the use of manpower or paint rollers. In fact, human feet need never leave the ground while facilitating the painting of towering structures in record time.

Robotics in commercial painting is revolutionizing the industry, and as painters, we’re overjoyed.

Technology has always been an essential part of commercial painting. The task of painting the exterior or vast interior of a commercial building requires mastery of scale, height, and safety. For example, painting teams have ben been using robotic lifts for decades to overcome the safety and maneuverability challenges of scaffolding. Spray applicators have also been incorporated more recently to achieve fast, even paint application over larger spaces.

It was only a matter of time before automation and robotics combined these two technologies to achieve something that is truly revolutionizing the commercial painting industry. The ability to automatically apply large swaths of paint in even coats will save not only days and weeks of man-hours for every task, it can also save lives.

Up until this singular mechanical evolution, commercial painting has been nearly the same for centuries. Most commercial painting takes place with people on scaffolds or lifts with paint rollers. The teams must use fall protection systems in order to stay safe as they increase the height of the area to be painted, and often painters must lean out to get a full area. Painting can only go as fast as humans could apply each layer in sections, relying on scaffolding or lift position and, at best, a spray applicator to facilitate the process. But no longer.

Combining the concepts of a lift and spray applicator with advanced robotic control, painters can now prep and paint vast surfaces in just a few hours. No more scaffold building, no more rolling paint by hand. The even coat applied by a commercial painting robot has transformed commercial painting timelines, introducing new scales of efficiency and productivity that outstrip centuries of commercial painting tradition.

Commercial painting robots aren’t just paint sprayers on robotic arms; they are advanced imaging and full-service painting apparatus. Robots that perform commercial painting are capable of handling the entire process, including inspection, sanding, priming, and painting the surface.

Using advanced imaging systems on the robotic arm or a manually operated drone, the first step of robotic commercial painting is to inspect the full scope of the surface. This will inform your painting team how the area needs to be prepared for the paint job. It will quickly become apparent whether the surface needs to be cleaned, stripped, or even maintained before the coating can begin.

Using a light abrasive medium, the robot painting arm is capable of preparing surfaces through sanding. The sanding can allow the robot to strip away old layers of paint, rust, and mildew from the building so that your new layer of paint starts with a fresh surface. Sanding is evenly applied with mathematical precision which strips away just enough to make the surface receptive to a new layer of paint an sealant.

The next step is applying a primer to the sanded surface. Each paint formula in your choice of color will be paired with the right primer for your climate, wall materials, and building condition. Primer is applied evenly using the spray application method, typically in two perfect coats as the spray arm passes over each section.

The primer is allowed to dry and, often, it is re-textured with light sanding to make it ideally receptive to the primary coat of paint. Paint in the client’s choice of color and finish is applied over the primer and allowed to cure. If a final sealcoat has been determined to be the best way to finish the job, it will be applied last.

It is likely that a final inspection will then take place using drones or robotic arm imagery to confirm that each section perfectly meets the desired specification.

In addition to being inspiring as only a giant robotic arm can be, there are several distinct benefits to using robotics in commercial painting. Having your building painted using robotics or incorporating a painting robot into your coatings business will ensure efficiency and safety for everyone involved.

Commercial painting is typically heavy on the man-hours needed to apply a paint roller to every inch of large commercial or public buildings. The robot, however, needs only a few minutes to coat each section of the building, and takes seconds – not hours – to reposition to adjacent and ever-higher sections. This alone can save hundreds of labor hours, and the wages required to supply them, for every future commercial painting project.

In addition to saving on labor, you are also saving time. The robot can paint a commercial building in hours and days instead of weeks and months. Once you’ve watched one of these robots efficiently position and apply layers of paint in large swaths, there’s no denying that every commercial painting project will be completed exponentially faster.

With a robot wielding the paint, no one needs to take their feet off the ground. The robot requires only a small team of operators on the ground to direct the job, which means no fall protection needed, because there is no risk of falling.

As the labor market contracts, adding robotics to job that traditionally takes a large number of people is an excellent way to tackle the labor shortage in the most efficient and inspiring way possible.

How many types of robots can be used in robotic painting? You might be surprised. Even though robotic commercial painting is relatively new, there are already several types of robots in the industry able to handle interior and exterior jobs painting walls, floors, ceilings, and structures.

Drones allow for visual inspection over large spaces and at scale. In some cases, drones have been equipped with hoses and spray capabilities for targeted paint application.

Autonomous commercial painting systems include software that allows the drone to position itself over an even grid. Autonomous painting systems work best for large rectangular buildings with uncomplex painting schemes where the robot can easily predict where to apply the next section of paint, and can do so with minimal human oversight.

While these systems can function autonomously for a time, they still require teams on-site to set up the system, enter the parameters, and troubleshoot if issues come up. This can be a challenge for some teams.

Semi-autonomous systems are directed by human operators through a control panel. Each section is programmed individually so the robot can handle more dynamic paint jobs with the benefit of experienced commercial painters operating the system.

The semi-autonomous robotic painting system used by PaintJet not only applies paint more quickly and with greater mobility than human painters, it achieves unprecedented quality in three ways. First, it uses advanced imaging to assess the conditions and prepare the surface for the highest quality adhesion. Next, it applies sanding, primer, and paint using a high-precision application. Finally, it uses AI to combine facts about conditions and paint formulas to predict the maintenance lifecycle of the finish it just applied.

The operators provide direction, oversight, and the ability to handle any surface, angle, or detail beyond what the robot could calculate for on its own.

Of course, what we’ve seen today is only the beginning. Automation and robotics are both advancing at a rapid pace, and the future for robotics in commercial painting is potentially vast. From AI to 3D printing technology, there are many innovations yet to be incorporated into robotic painting technology simply waiting for the R&D to make it happen. In the next decade, we expect to see huge leaps and bounds in both automation and advanced painting techniques based on the advanced technology already in use today.

What an AI can do through a camera has advanced further than most people realize. Right now, robots can use advanced imaging technology to capture surface conditions, the surface’s environment, and historical maintenance. This helps the robot determine how to prep the surface to best receive the new finish and predict the performance of the new finish once applied.

Everyone is talking about what AI can do in a software environment, but AI also has a great future in facility maintenance. Today, AI in PaintJet robotic painting can process data regarding a building’s external conditions, historical data, and paint manufacturing requirements to create a comprehensive view of the job. AI can then predict the paint maintenance lifecycle so that building managers know exactly when to schedule follow-up and repainting services.

If you are considering hiring a robotic painting contractor like PaintJet, there are few things to consider before making your decision. You will want to ensure the team and their robots can handle the scope of your project, meet your timelines, is skilled with the equipment, and can offer you a valuable experience.

Different painting robots can achieve different results. Smaller robots are ideal for interior jobs, while large-scale lift robots can quickly coat a building’s exterior with ease. Consider the types of commercial painting robots are used by the team and whether the scope of robotic capabilities will meet your needs.

How long will it take to finish the job? If you’re used to painting quotes by all-human teams, a shorter timeline for robot painting will likely be both surprising and pleasing.

What types of primer, paint, and coating can the painting robot handle? High-end paint robots can handle a wide range of finishes, including specialty finishes, to meet the needs of your building usage and materials.

PaintJet specializes in proprietary high-performance coatings that protect the surface from abrasion and corrosion, while offering superior durability compared to most commercial paints.

Compare your robotic painting quote to that of a human contracting team and see the difference between rapid machine painting versus a large team painting by hand.

You want a robotic painting team that knows its robots inside and out. A skilled team can quickly program the robot to complete your job and adapt to any unique details about your building or structures. They will offer superior speed, safety, and results.

As with any commercial painting team, you can always check the quality of their previous work. Explore the gallery and case studies of earlier projects to see how well the robot and its team perform together to achieve the desired results.

Seeing is believing. Check out how this manufacturing company got their building repainted on a 2 weeks notice or how this company rebranded their facilities on time and on budget.

Robots are changing the way that commercial painting is done, and the revolution couldn’t be more exciting. Both contractor teams like PaintJet and our clients are inspired to watch the robot work with no need for large teams or fall prevention systems because everyone is safely on the ground while the robot performs large painting tasks at record speed.

We can’t wait to embrace the next generation of painting robotic advancement. If your commercial buildings are in need of interior or exterior repainting and you are to experience the future of painting, contact us today.

15 Years Painting industry expertise @ PPG, PaintZen, CertaPro and industrial painting contractor

Often, your paint finish is the first sign that a commercial building needs repair. Peeling, fading, discoloration, or bubbling paint can indicate moisture or just the usual elements of age and wear.

Keeping your facility in top condition requires constant maintenance. Commercial and industrial building managers are constantly taking care of repairs and touch-ups to maintain the quality of the facilities.

For property managers, asset managers and general contractors, keeping industrial assets in good condition is essential for maintaining their market worth over time.

© PaintJet. All rights reserved. Privacy Policy